Product Links

CAT Toolholders

CAT tooling comes in a range of sizes designated as CAT 30, CAT 40, CAT 50, etc. The number refers to the Association for Manufacturing Technology’s (formerly the National Machine Tool Builders Association (NMTB)) taper size of the tool. CAT toolholders were developed for the Caterpillar tractor company and are sometimes called V-Flange Tools. They are of a robust design used primarily for a range of applications from precision machining to heavy duty roughing. This type of toolholder is supported by ATC (automated tool change) technology. The toolholder body is pulled into the milling spindle with the aid of a retention knob or pull stud and centered via the taper contact. Spindle speeds up to 12,000 rpm are standard with steep-taper tools. CAT toolholders will accept both imperial and metric sized tools.

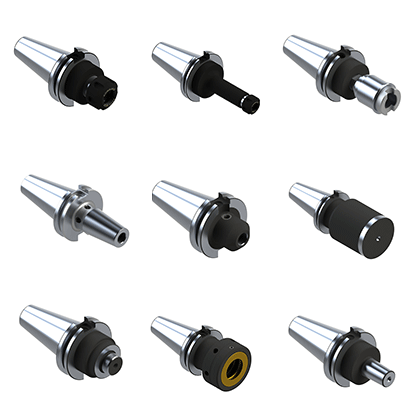

CAT40 & CAT50 ToolHolders

All Redline toolholders are proudly made in the USA with American 8620 steel. Our craftsmanship and attention to detail in a quality tool, provides the performance required by the American machinist. Our toolholders are designed with AT3 or better shank taper accuracy and are concentric to < .0002 (.005 MM or 5 microns), placing the tool precisely on the machine spindle centerline. This accuracy promotes minimal tool wear and replacement, saving you time and money. ER11 – ER16 – ER20 – ER25 – ER32 – ER40 – TG100 – TG150 collet chuck holders, shrink fit holders, hydraulic chucks, endmill holders, facemill (shell mill) holders, tap (rigid and tension & compression) holders, Jacobs taper holders, slitting saw holders, stub arbor holders, Morse taper holders, boring head holders, adapters, toolholder packages, and more.