Product Links

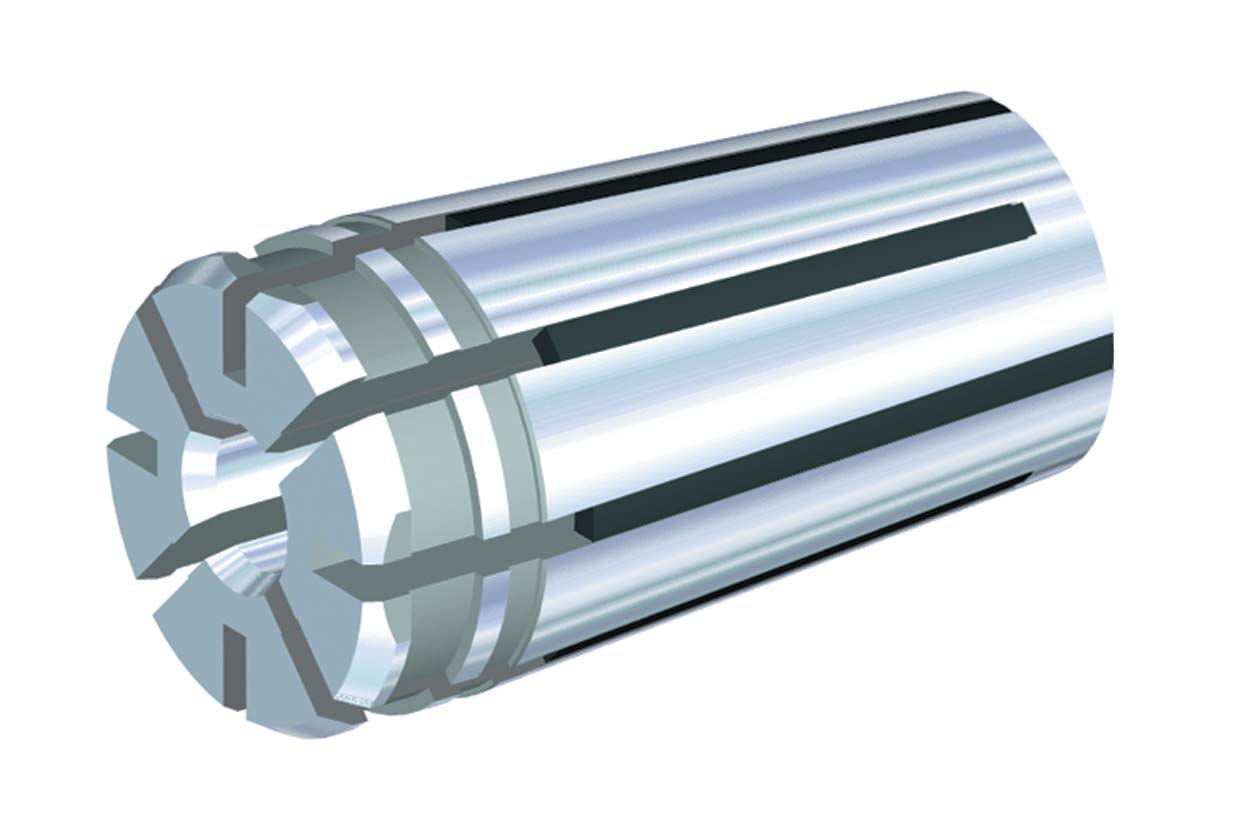

Collets

What is a Collet?

A collet is like a chuck in that it applies clamping force around a tool, holding it in place. The difference is that the clamping force is applied evenly by forming a collar around the tool shank. The collet has slits cut through the body forming flexures. As the collet is tightened, the tapered spring design compresses the flexure sleeve, gripping the shaft of the tool. The even compression provides an equal distribution of clamping force resulting in a repeatable, self-centered tool with less runout. Collets also have less inertia resulting in higher speeds and more accurate milling. They provide a true center and eliminate the need for a sidelock holder that pushes the tool to the side of the bore resulting in an unbalanced condition.

What type of collets are there?

There are two types of collets, workholding and toolholding. RedLine Tools provides a selection of toolholding collets and accessories such as Rego-Fix ER, Kennametal TG, Bilz tap collets, Schunk hydraulic sleeves and coolant sleeves.

ER Collets

ER Collets are the most popular and widely used collet. Developed by Rego-Fix in 1973, the ER collet derived its name from the already established E-collet with the first letter of their brand Rego-Fix. These collets are manufactured in a series from ER-8 through ER-50 with each number referring to the bore in millimeters. These collets are only used with tools that have a cylindrical shaft such as endmills, drills, thread mills, taps, etc.ER collets have some clear advantages over traditional set screw holders.- Runout is much lower extending tool life

- Increased stiffness provides better surface finish

- Better roughing abilities due to increased stiffness

- Self-centering bore

- Better balance for high speed milling

- Holds the tool more securely

- Collets and collet chuck nuts are consumable items and much less expensive to replace than the toolholder. Look for fretting and scoring on the collet that indicates it spun inside the collet chuck. Similarly, check the inside bore for the same kind of wear, indicating a tool spun inside the collet. If you see such marks, burrs on the collet, or gouges of any kind, it’s probably time to replace the collet.

- Keep the collet clean. Debris and dirt stuck in the bore of the collet can introduce additional runout and prevent the collet from gripping the tool securely. Clean all surfaces of the collet and tools with a degreaser or WD40 before you assemble them. Make sure to dry thoroughly. Clean and dry tools can double the holding force of the collet.

- Make sure the tool is inserted deep enough into the collet. If they are not, you will have increased runout. Typically, you will want to use at least two-thirds of the collets length.

Recommended torque values:

| Collet Size | Nut Type | Collet Capacity | Torque |

| ER11 | Hex | .0390 - .0980 | 6 ft lbs |

| ER11 | Hex | .1180 - .2560 | 24 ft lbs |

| ER16 | Hex | .0390 | 6 ft lbs |

| ER16 | Hex | .0590 - .1380 | 15 ft lbs |

| ER16 | Hex | .1570 - .1770 | 30 ft lbs |

| ER16 | Hex | .1970 - .3940 | 46 ft lbs |

| ER20 | Hex | .0390 | 12 ft lbs |

| ER20 | Hex | .0590 - .2560 | 25 ft lbs |

| ER20 | Hex | .2760 - .5120 | 60 ft lbs |

| ER25 | Hex | .0590 - .1380 | 18 ft lbs |

| ER25 | Hex | .1570 - .1770 | 40 ft lbs |

| ER25 | Hex | .1960 - .2950 | 60 ft lbs |

| ER25 | Hex | .3150 - .6690 | 80 ft lbs |

| ER32 | Hex | .0780 - .0980 | 18 ft lbs |

| ER32 | Hex | .1880 - .2910 | 100 ft lbs |

| ER32 | Hex | .3150 - .7870 | 100 ft lbs |

| ER40 | Hex | .1180 - 1.0230 | 130 ft lbs |

| ER50 | Hex | .2360 - 1.4170 | 180 ft lbs |

TG Collets

TG or Tremendous Grip collets were developed by

the Erickson Tool Company. They have a 4 degree taper which is much less than

ER collets that have an 8 degree taper. For that reason, the grip force of TG

collets is larger than ER collets. TG collets also have a much longer grip length resulting in a larger surface to grip with. On the

flip side, they are more limited in the range of

shank collapsibility. Meaning you may have to purchase more collets than you

would ER collets, to work with your range of tools.

Because TG collets grip carbide tooling much tighter than ER collets, they are ideal for end milling, drilling, tapping, reaming, and boring. RedLine Tools offers the two different sizes; TG100 and TG150.

- Original ERICKSON standard

- 8° inclusion angle taper

- Standard design accuracy to DIN6499

- Grips on back taper for maximum feed rates and accuracy

Recommended torque values:

| Collet Size | Nut Type | Collet Capacity | Torque |

| TG100 | Hex | .0781 - 1.0000 | 75 ft lbs |

| TG150 | Hex | .5000 - 1.5000 | 100 ft lbs |

Tap Collets

Quick-Change tapcollets are for synchronous tapping systems using a Rigid tap holder or tension & compression tap holders that allow you to change and secure taps in seconds. The tap fits on the square and is held securely by the locking mechanism. The collet bore is measured to the tool diameter, with square drive for accuracy. By using Bilz Quick-Change tap collets, the time to change out taps is greatly reduced. On transfer lines and special application machines, cost savings can be significant.

- Quick-Release design - reduced down time of the machine

- Quicker tool change of the adapter - reduced down time

- Extend tool life

- Low friction - lower wear, less maintenance required

- No slipping or twisting of the tap in adapter

Hydraulic Sleeves

Intermediate sleeves, or hydraulic sleeves, utilize hydraulic pressure supplied by a hydraulic chuck to collapse the sleeve around the shank of the tool. They extend the available tool shank diameters from 3MM to 25MM for a single hydraulic tool holder. They tend to control runout better than collet chucks and offer vibration-dampening characteristics to improve tool life and part finish. The real benefit is their slim design, which allows more clearance around parts and fixtures than collet chucks or mechanical milling chucks.

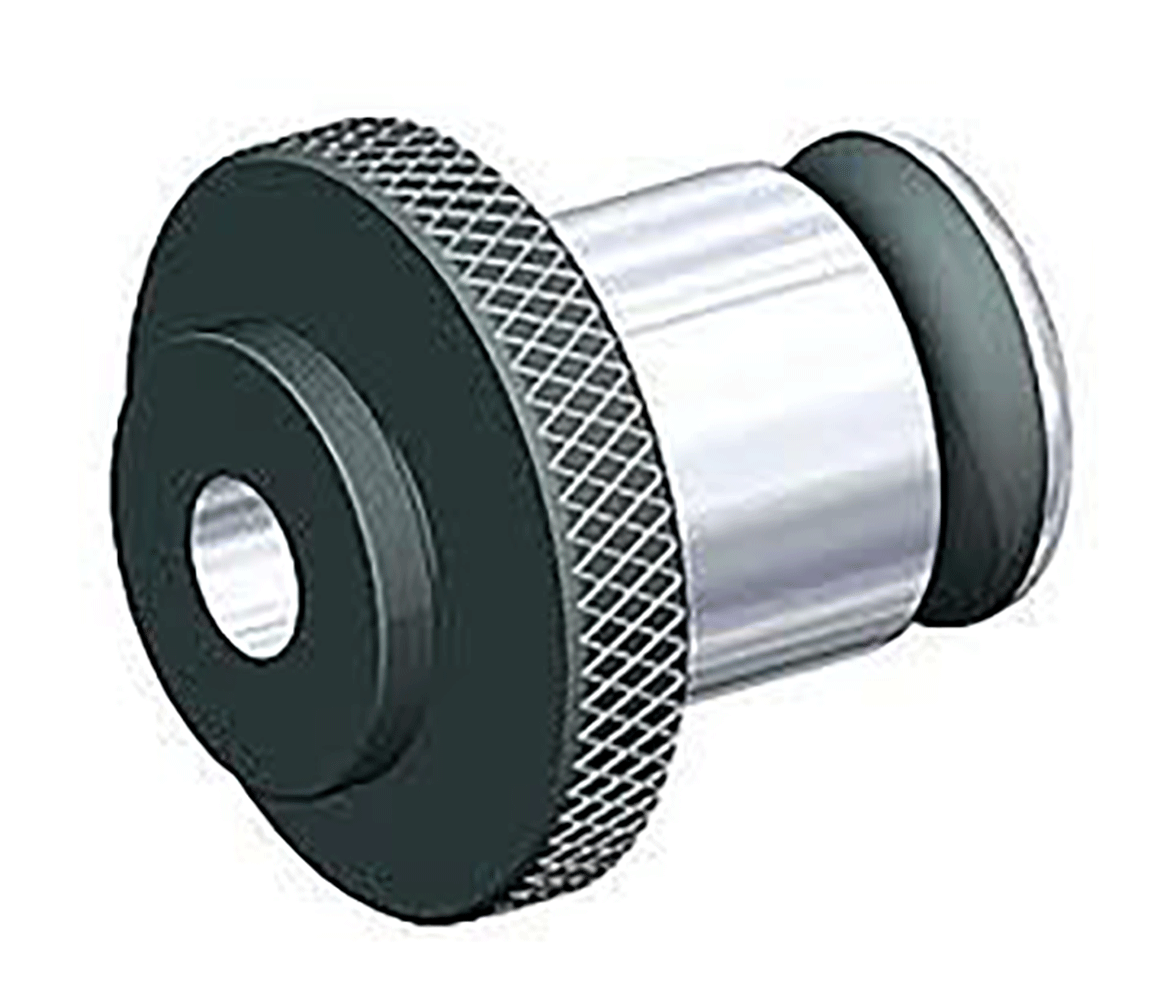

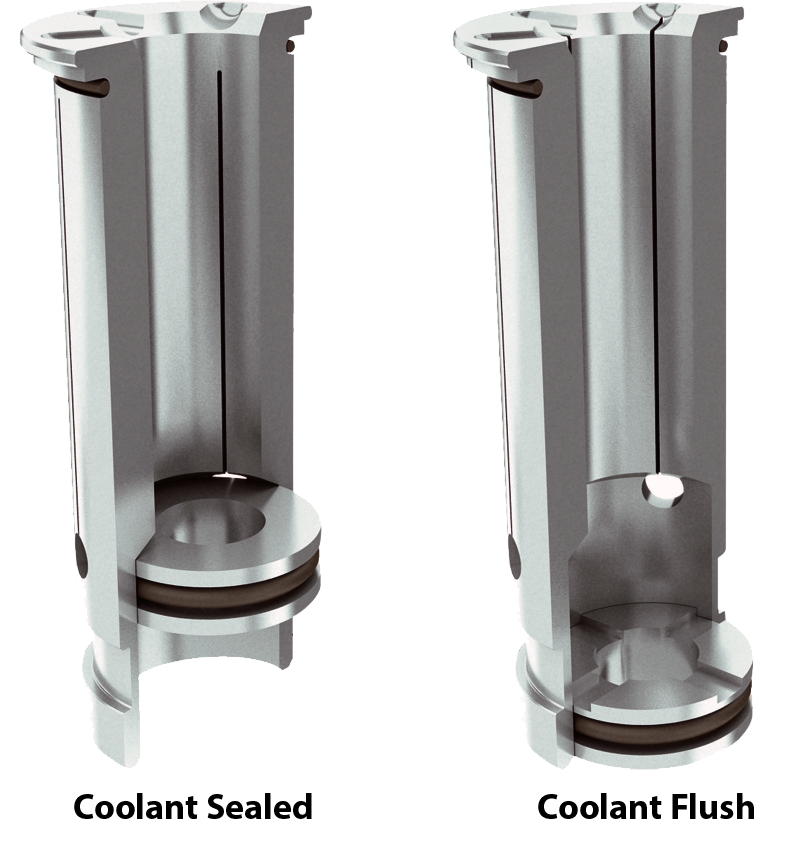

Coolant Seals

Coolant seals prevent the loss of coolant and pressure on tools and holders with inner coolant passages such as drills, end mills, taps, reamers and collet chucks. By applying maximum coolant pressure directly on the cutting tip, higher speeds & feeds and longer tool life can easily be attained. No special wrenches or hardware are needed to install. Installation is quick and easy allowing for zero down time. Once the seal is installed you will notice the constant pressure that is emitted. Your tools will perform at peak performance with no adverse effect on accuracy or clamping ability.

- Uses existing nose piece assembly

- Keeps collet free from dirt and chips. Especially helpful preventing ferrous chips and dust during iron milling

- Tools do not need to extend completely through the collet in order to seal

- Use with drills, end mills, taps, and reamers

- Sizes available to fit most collet systems

Collet Maintenance

Collet maintenance is essential to improving tool life and cutting performance for all CNC milling centers. Highlighted in this video are methods for cleaning your collets, torquing your collets, TIR rule (concentricity), and examples of damaged collets.