Product Links

Thread Mill Information

Thread mill programs for milling machines can be found here

Thread milling first appeared about 25 years ago in response to NASA’s need to machine high-quality threaded holes in difficult materials such as Titanium, Hastelloy and Inconel. Thread milling has become a more cost effective method to process and produce threads in hardened materials up to 70 Rockwell, than by the older method of using taps. Thread milling has many advantages of thread making over tapping.

Thread Mills achieve their thread cutting ability by a method called helical interpolation. Helical interpolation involves simultaneous circular X and Y axis movement combined with an axial (Z) feed and a defined pitch. The helical interpolation tool path makes thread mills versatile with the ability to cut right and left hand threads, internal and external threads, and produce a variety of thread sizes.

Thread Mills vs. Taps

• Thread mills can adjust the tolerance of the thread

• Thread mills can cut material in progressive passes which is better for hard materials

• They won’t get stuck in parts if they break

• They can cut different thread sizes with the same tool

• They can cut odd sized threads

• They can be used to back chamfer a hole

• They require much less horsepower from your machine than tapping

• Thread mills are available in carbide which most taps are not

• Thread milling achieves a higher quality thread than tapping because chip removal is more efficient leading to a better result

• Most types of thread taps require a hole bigger than the threads resulting in a weak thread.

• Thread milling creates a thread with a smaller tolerance for a stronger thread

Types of Threads

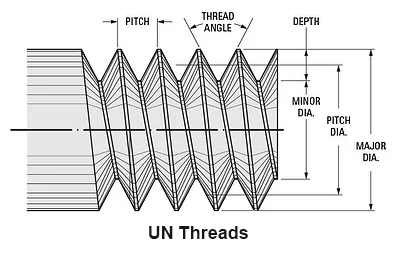

ISO Metric, American UN – Uses a 60° thread angle. These threads are used for general purposes.

NPT – National Pipe Tapered is an internal tapered 60° thread used on pipes and fittings. The taper thread will pull tight and form a fluid-tight seal. This type of thread requires a sealant and is not suitable for high-pressure applications.

NPS – National Pipe Standard has a 60° straight thread.

NPTF – This is a 60° degree NPT thread that is used for high pressure or fuel applications.

British Standard, Whitworth – Uses a 55° internal thread form and is often used when a watertight seal is needed.

UNJ, MJ – Often used in the Aerospace industry and feature a radius at the root of the thread.

Types of Thread Mills

For Technical and Application Information including Feed Speeds, HEM Slotting, Facing, Helical Ramping, Straight Line Ramps, Long Reach Adjustments, Eliminating Wall Taper When Finishing, Ball Node Endmill Adjustments, Surface Finishing.

.png)

.png)

.png)

.png)